The whole point of using renewable energy is to create energy from a clean source so that we can help protect our planet. Using solar panels is an excellent way to do that, and it helps to minimize waste.

Solar panels are mainly made of glass, aluminum, and silicon, which are all recycleable materials. Through various steps, thermal processing, and the assistance of heavy machinery, solar panels can be broken down and recycled to help keep the planet clean.

How are solar panels recycled? What can I do to help protect the planet?

Recycling Solar Panels

There are various steps that recycling plants take to recycle solar panels:

- Removing the aluminum frame (100% reusable)

- Separating the glass along a conveyor belt (95% reusable)

- Thermal processing at 500 degrees Celsius

- This allows for the evaporation of small plastic components and allows the cells to be easier separated.

- Etching away silicon wafers and smelting them into reusable slabs (85% reusable)

-Source

Once the solar panel has been completely taken apart, each componant can then be recycled individually.

Some countries, such as European nations, have increased their solar energy usage, and because of that, they have increased their recycling market as well. If we do not recycle these solar energy systems, then they just end up in landfills, which defeats the point of using clean energy.

The United States is behind Europe on their recycling programs. Washington State was the first state to to pass a solar product stewardship law, and hopefully many more states follow their good example. If all nations can pass laws to make sure that solar panels stay in recycling plants and out of landfills, then we will see a difference in the years to come.

The Recycling Process

First, all materials must be gathered in a recycling plant. There, workers separate the individual layers and pieces of each solar cell. The glass parts and aliminum pieces are disassembled and separated. The glass is 95% recycleable, and 100% of the metal from the solar panels can be reused.

The rest of the materials go through a thermal processing treatment at 500 degrees celsius. This helps to evaporate the covering plastic from the silicon layers. Next, the cell modules are physically separated, and 80% of the modules can be reused.

The rest of the silicon undergoes a chemical treatment to etch away the anti-reflection coating from the silicon wafers using phosphoric acid. Those broken wafers are then melted down and 85% of the melted silicon can then be reshaped and reused.

What Are Solar Panels Made Of?

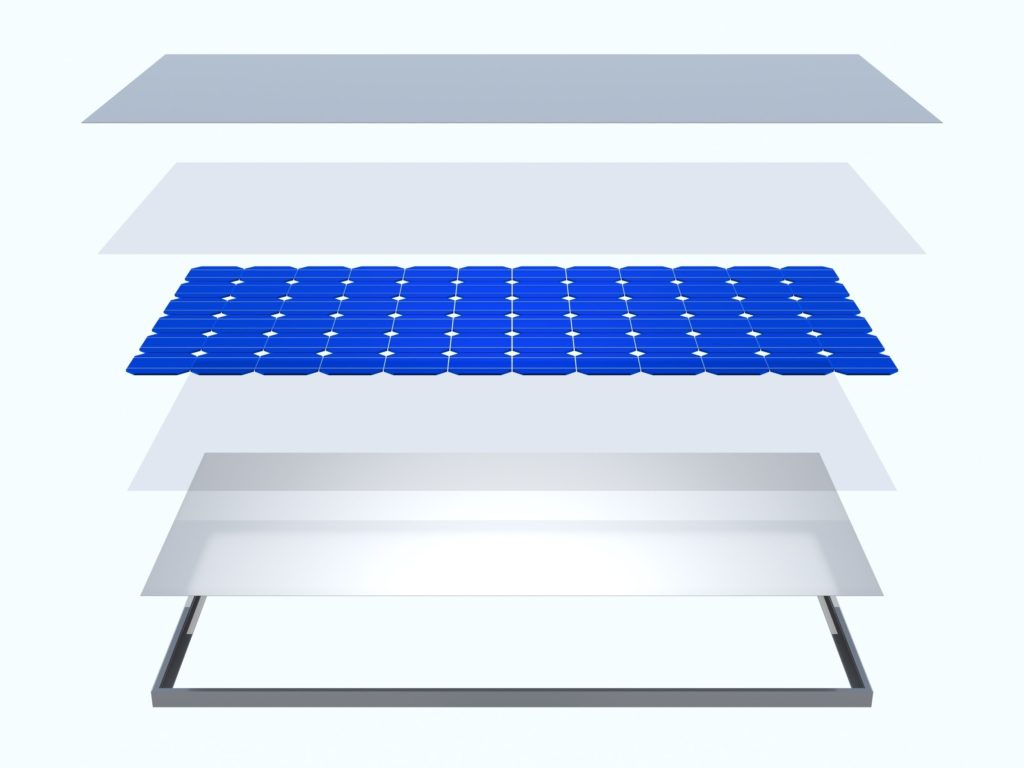

Solar panels are made up of smaller units, called solar cells. Each solar cell consists of multiple layers.

From top to bottom, the layers are glass, antireflection coating, metal contacts, two silicon layers, and a metal grid on bottom. These cells are held together by an aluminum frame, making up a solar panel.

Some more detail about each layer in the solar cell:

- The top layer of glass’s purpose is to protect the rest of the solar cell layers from anything that might damage them, such as dirt, debris, and hail. Without the glass, the solar cell would have no protection from the outside elements.

- The next layer is the antireflection coating. The antireflection coating allows sunlight to pass through it, but prevents the light from reflecting off of the shiny silicon layers and back out of the cell. This effectively traps the light inside the cell to use. Trapping the light helps to raise efficiency of the cell. Otherwise, most of the sunlight would reflect back out and would be useless.

- The metal contacts is just a wire grid that runs along the silicon layer below it. It allows electrons to easily pass through while holding the cells together in the solar panel.

- The silicon layers act as semi-conductors. Phosphorus is added to one of the silicon layers to give the element extra unbonded electrons. Boron is added to the other layer of silicon to create an opening for those electrons to go. When the extra electrons move from the phosphorus layer to the boron layer, the phosphorus layer is left with a positive charge (from lack of electrons) and the boron layer is given a negative charge (from the extra electrons). This imbalance of charges gives the cell an electric field.

- The metal grid on top of the silicon layers and the metal at the bottom of the silicon layers act as conductors to create a circuit for the electric field. This circuit creates the direct current (which is then converted into alternating current) that we use to power our homes.

Because the main ingredients for solar cells and solar panels is mostly glass, silicon, and metal (aluminum), solar panels can be almost completely recycled.

Glass

As explained above, the top layer of each solar cell in your solar panel is made of glass. This glass protects your solar energy system from damage. However, if your solar panel is old and no longer working efficiently, then it is probably time to retire it.

Luckily, the glass on your solar panel can be recycled. Glass is sent to a processor where it can then be cleaned, sorted out, and crushed down into tiny pieces. These pieces are then furnace-ready to be recycled into new glass jars, bottles, or even new sheets for solar panels.

Silicon

The silicon layers, or silicon wafers, are the most important layer of each solar cell and must undergo a thorough and innovative process to remove the silicon wafers from the constructed solar panel. Once these wafers are removed, they can be reused in new solar panels.

The first step in the silicon recycling process is to completely remove any trace elements from the other layers of the solar cell that might have gotten onto the silicon during the separating process. To do that, workers dissolve any residue of silver and aluminum by using nitric acid, and then potassium hydroxide.

Next, workers remove the anti-reflection coating and the emitter on the surface. This is done using an etching paste containing phosphoric acid.

The silicon wafers are then put into a furnace and heated for two minutes at 320, 340, 360, 380, and 400 °C.

These newly cleaned and recycled silicon wafers are almost identical to brand-new silicon wafers, and are just as efficient. They are then ready to be placed back into solar cells and made into solar panels.

Aluminum Frame

Recycling aluminum is a fairly easy task. First, the aluminum must be gathered and then sent to a treatment plant. There, it is cleaned and sorted to be melted down. When the aluminum is melted down, it turns into molten aluminum. The melting process removes any impurities on the aluminum such as ink or coatings.

The aluminum is then formed into large ingots where it can be reshaped and turned into a new aluminum structure.

Why Should You Recycle Your Solar Panels?

Recycling solar panels has only benefits and zero drawbacks. Because the solar industry is growing so quickly (at over 64 million solar panels per year), the impact of the potential waste of those units could be devastating. If we do not recycle our solar energy systems, there could be a huge negative impact on the environment, which defeats the purpose of renewable energy.

There are many benefits to recycling solar panels, such as creating new jobs for recycling plant workers and delivery drivers.

“Solar panels contain relatively rare elements of high value. When they are recycled, it enhances the sustainable growth of photovoltaics by creating a secondary stream of valuable materials. In this way, recycling can help relieve pressure on panel prices.”

–Dr. Vasilis Fthenakis

If we want to keep producing solar panels, we need to be able to reuse the rare earth metals that solar panels need to function, lest we eventually run out of materials. We want to stop using fossil fuels and switch from nonrenewable to renewable energy, but if we do not recover those rare materials from old solar panels, then we will not be able to make that transition.

Solar panel recycling has been mandatory in Europe since 2012. The United States does not have any kind of laws or mandates regarding solar recycling, but the U.S. needs to step up its game if we are to make the change to clean energy.

What Can You Do?

So, as a solar power consumer, what can you do to make a difference? When you install your solar panels, make sure to talk to your supplier about any recycling programs that they may have in place. If they do not have any, then let them know that they should, and that you would be willing to pay for recycling. If there is enough consumer demand, then the companies will see how important recycling programs are to their buyers.

If it is not possible to recycle your solar panels, then take initiative and search for other recycling programs in your city or community. Anything you can do will make a difference for the planet.